Our Contribution

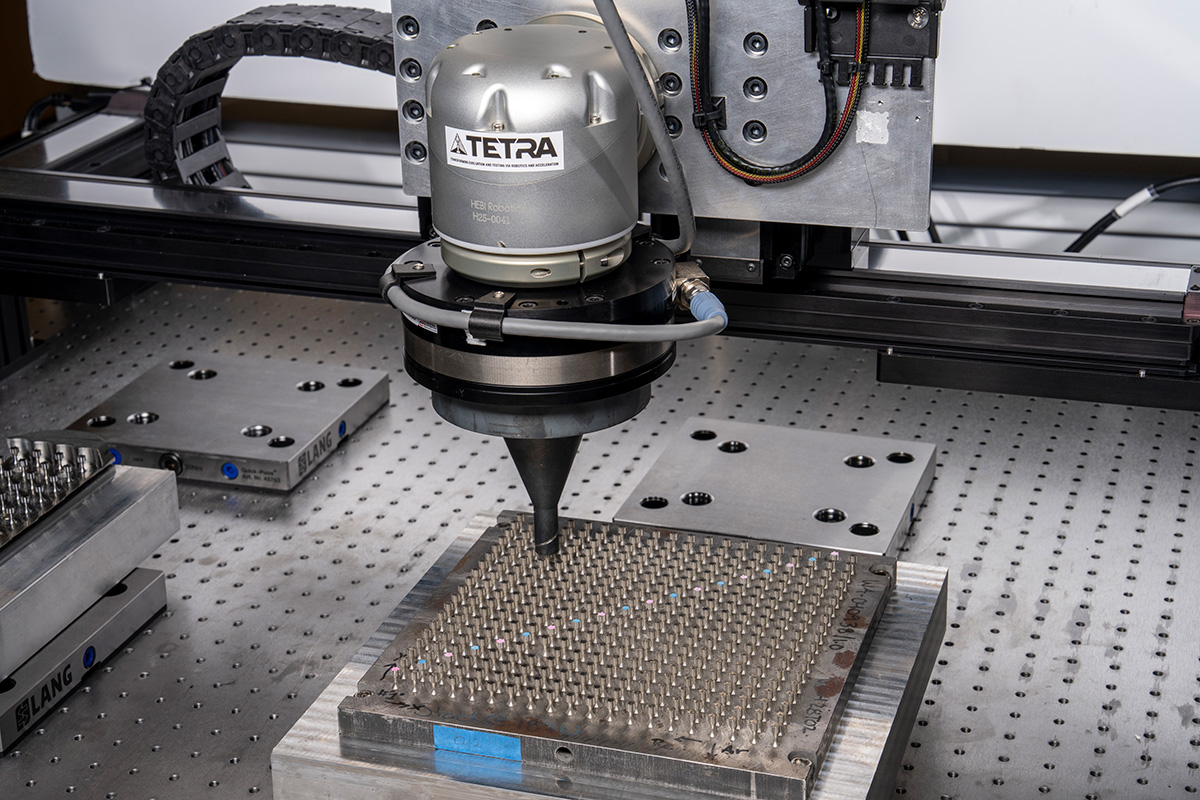

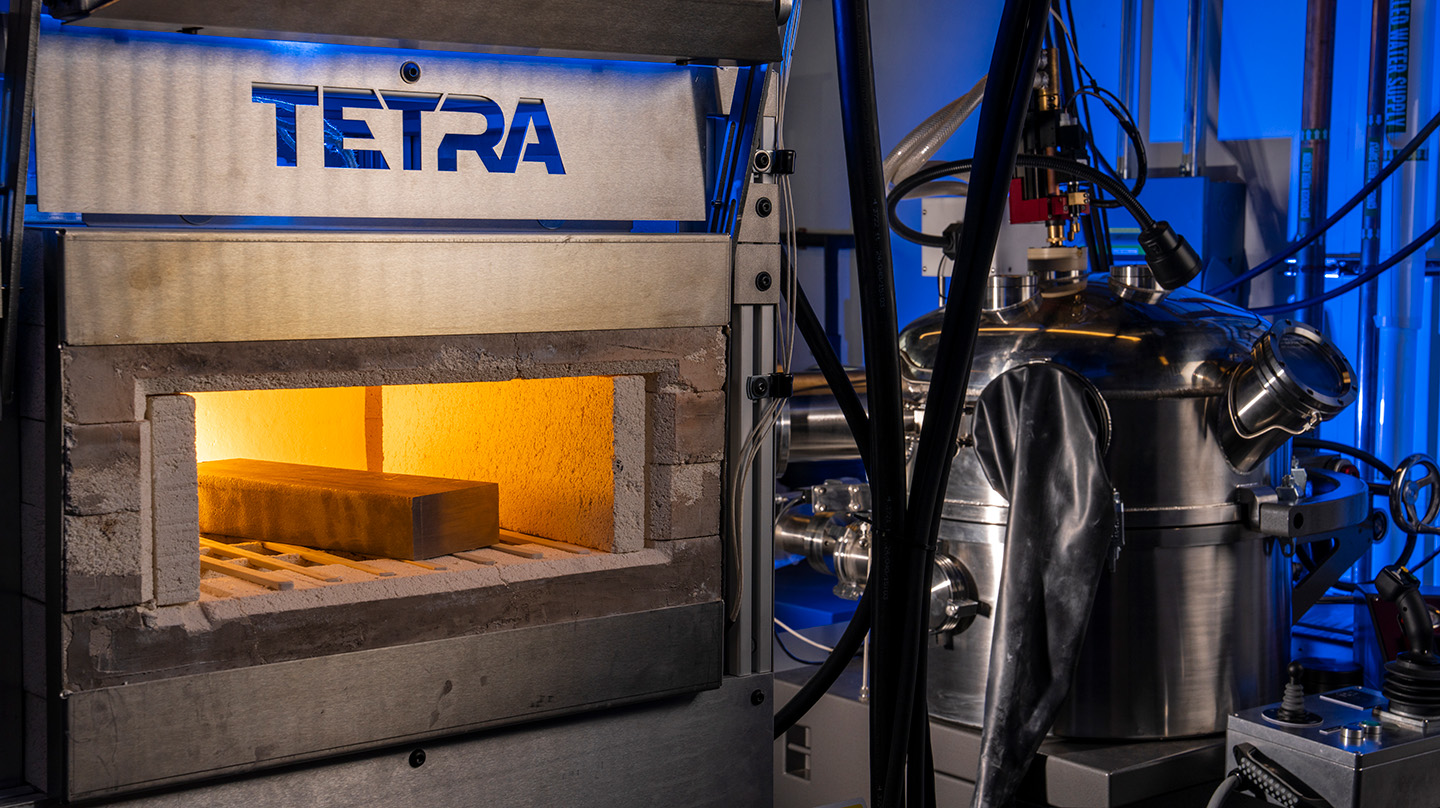

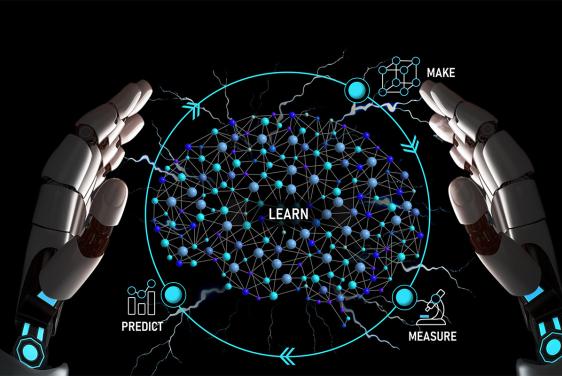

APL researchers, funded by the Department of War’s Industrial Base Analysis and Sustainment Program, are developing a novel materials science paradigm called Transforming Evaluation and Testing via Robotics and Acceleration, or TETRA. The name is a reference to the materials science tetrahedron—a conceptual framework for visualizing the relationship between the processing, structure, properties, and performance of a material. TETRA represents a radical reimagining of this framework, and APL has stood up an innovative facility to realize this vision. By integrating robotics and accelerated synthesis and testing methods, APL researchers are developing and validating a suite of tools that makes it possible to produce and evaluate materials at an unprecedented rate. In addition to fabrication via additive manufacturing, the TETRA lab features a state-of-the-art melting furnace for ultrafast synthesis of custom castings from raw material, custom heat treatment furnaces and hot forging equipment for shaping material and modifying its microstructure, and robotic mechanical property measurement. This combination of capabilities makes TETRA an all-in-one materials research and development facility—the first of its kind. The TETRA team also envisions bringing in existing capabilities that employ artificial intelligence to discover novel materials for extreme environments, including creating an AI co-investigator to work alongside researchers to autonomously design and test materials.