News

An Accelerated Paradigm for Developing Mission-Critical Materials

Audio generated using AI voice technology.

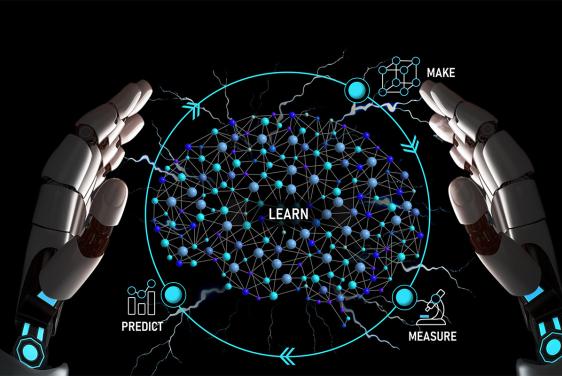

Scientists and engineers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, are developing a novel materials science paradigm — one that strategically applies artificial intelligence and robotics — that holds promise to dramatically accelerate the process of designing, testing and optimizing metal components for the defense industrial base.

“The Department of Defense needs legacy metallic components to maintain existing systems, but it also needs advanced materials to unlock enhanced performance. The problem is that the industrial base currently can’t keep up with demand for these crucial components,” said Sal Nimer, who is the assistant program manager for APL’s Science of Extreme and Multifunctional Materials program and leads this work. “Furthermore, the slow process for proving out and qualifying alloys hinders our ability to rapidly deploy new cutting-edge materials.”

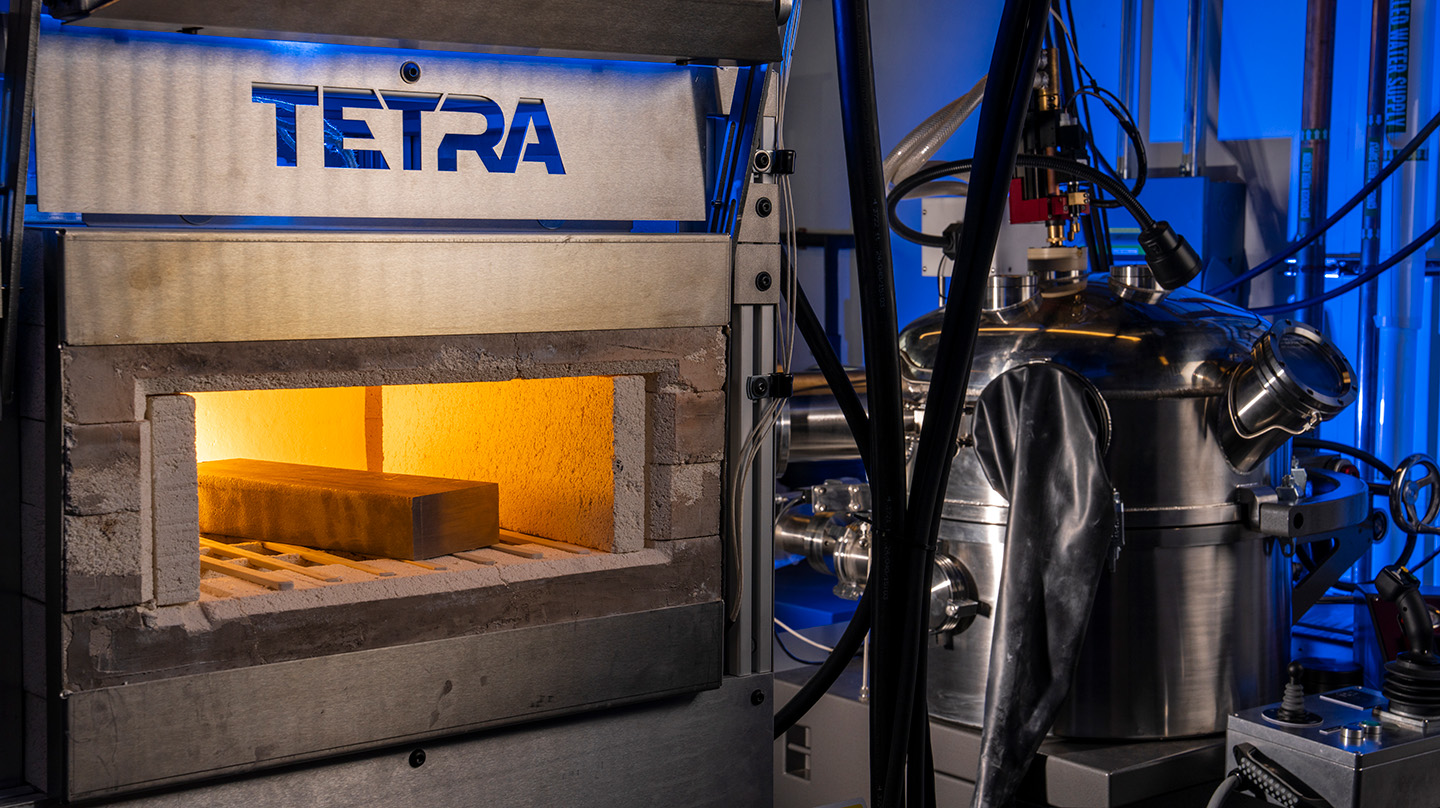

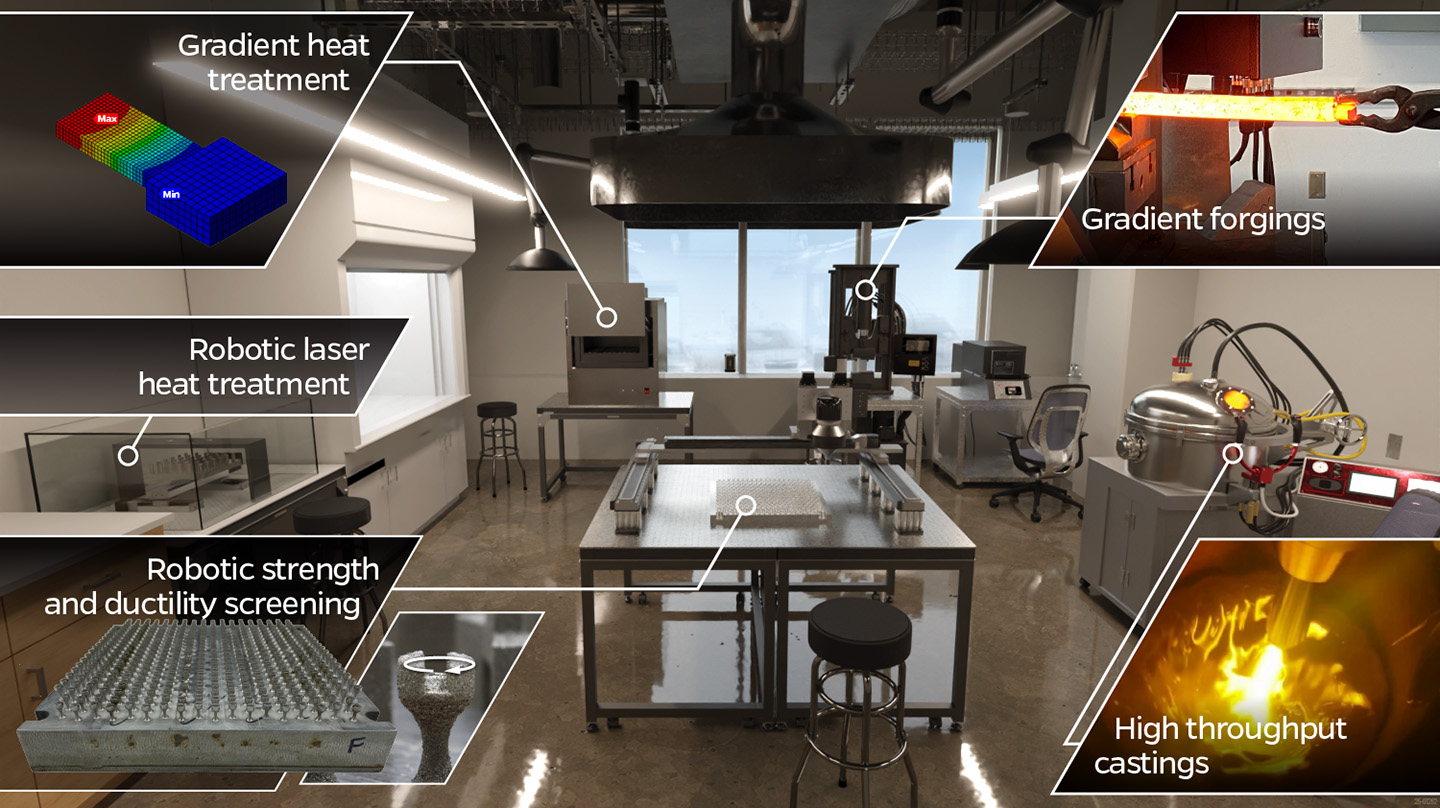

APL’s new effort, funded by the DoD’s Industrial Base Analysis and Sustainment Program, is called Transforming Evaluation and Testing via Robotics and Acceleration, or TETRA. The name is a reference to the materials science tetrahedron, a conceptual framework for visualizing the relationship between the processing, structure, properties and performance of a material. In this effort, APL is reimagining the traditional tetrahedron. “By integrating robotics and accelerated synthesis and testing methods, we’re developing and validating a suite of tools that makes it possible to produce and evaluate materials at an unprecedented rate,” Nimer said.

“When developing materials for defense needs, it’s not just about the composition of the alloy or system — it’s also about how you shape, treat and refine it,” said Morgan Trexler, who leads the research program area in APL’s Research and Exploratory Development Mission Area. “TETRA has potential to be game-changing because it allows us to simultaneously consider every variable that impacts performance, which until now, has been painstaking and time-consuming, sometimes taking months to achieve what TETRA can accomplish in just a matter of days.”