Advanced Manufacturing

Accelerating national readiness and resilience through mission-driven manufacturing innovation

Leveraging AI-driven design, precision fabrication, novel sensing, materials process development, and hybrid electronics packaging, APL delivers resilient, high-performance solutions that advance national defense, space, and infrastructure.

Featured

New Robotic Arm Opens Doors to Explore Future of Maritime Repair →APL has installed a state-of-the-art robotic arm to advance repair and manufacturing for the maritime industrial base. Using wire arc additive manufacturing and advanced sensing technologies, the system makes faster, more precise repairs of oversized components possible—strengthening fleet readiness and reducing costs. This innovation builds on APL’s commitment to supporting Navy sustainment and industrial agility.

Our Advanced Manufacturing Process and Capabilities

APL bridges early research to the creation of highly complex, operational prototypes for deployment to the front lines. Our advanced manufacturing capabilities create opportunities to optimize the timeline for fielding new systems, decrease overall risk, and ensure team continuity, from research, through engineering and fabrication, to mission deployment.

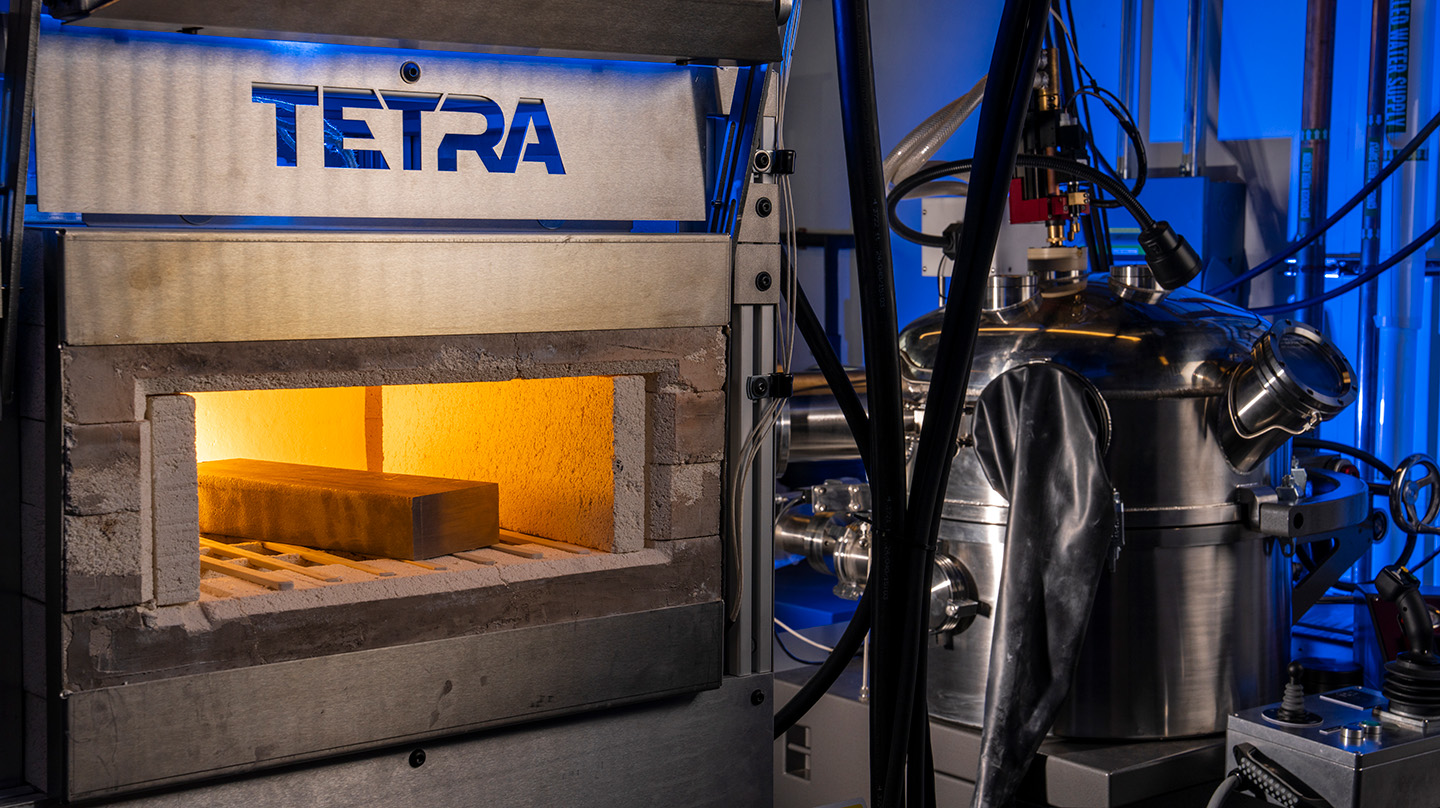

Materials Characterization

Analyzing material properties using tools like electron microscopy and X-ray diffraction to optimize performance for aerospace, defense, and energy systems and applications

Design and Planning

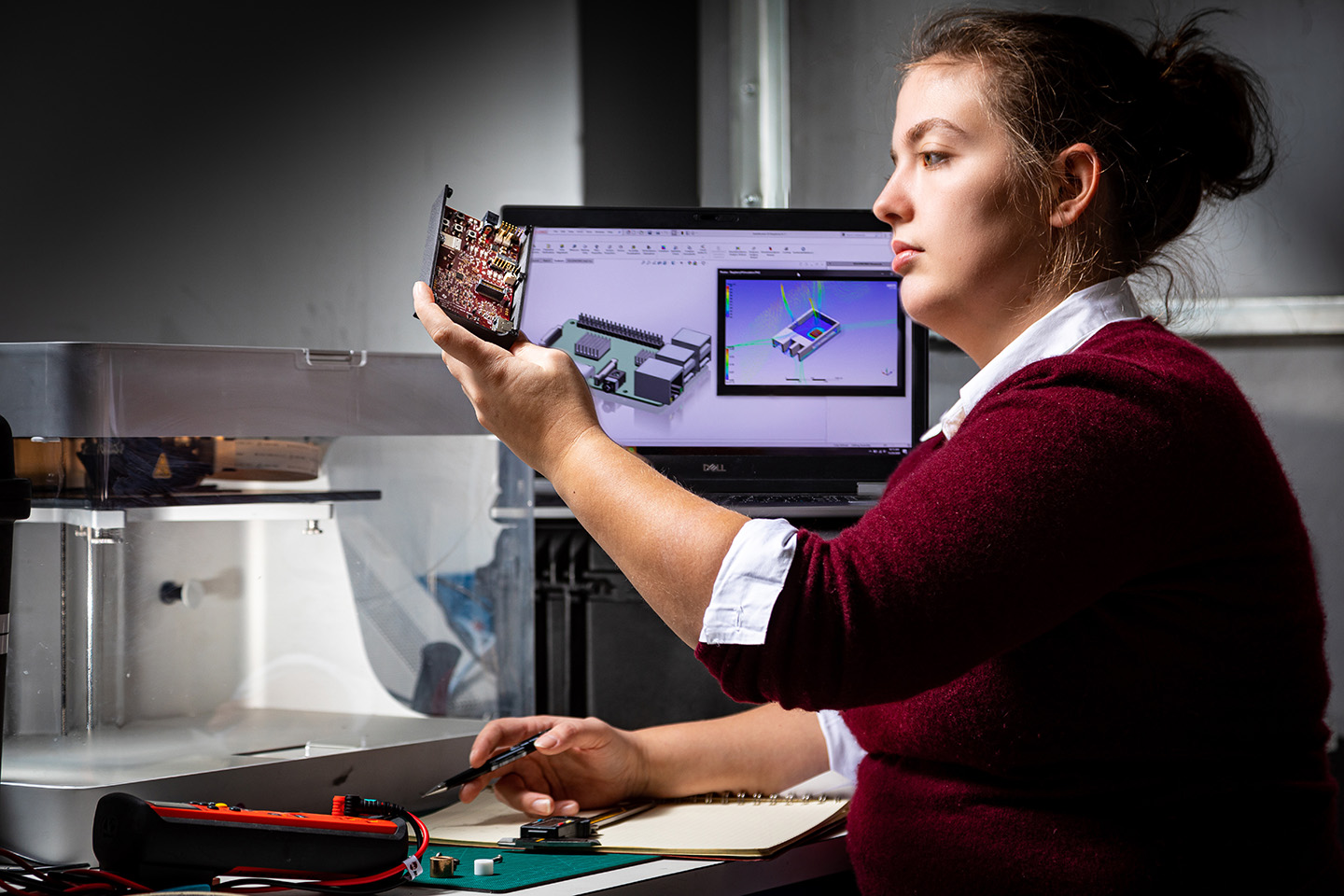

Designing using digital twins, CAD, and AI-driven simulations to streamline manufacturability, reduce costs, and accelerate prototyping for complex systems

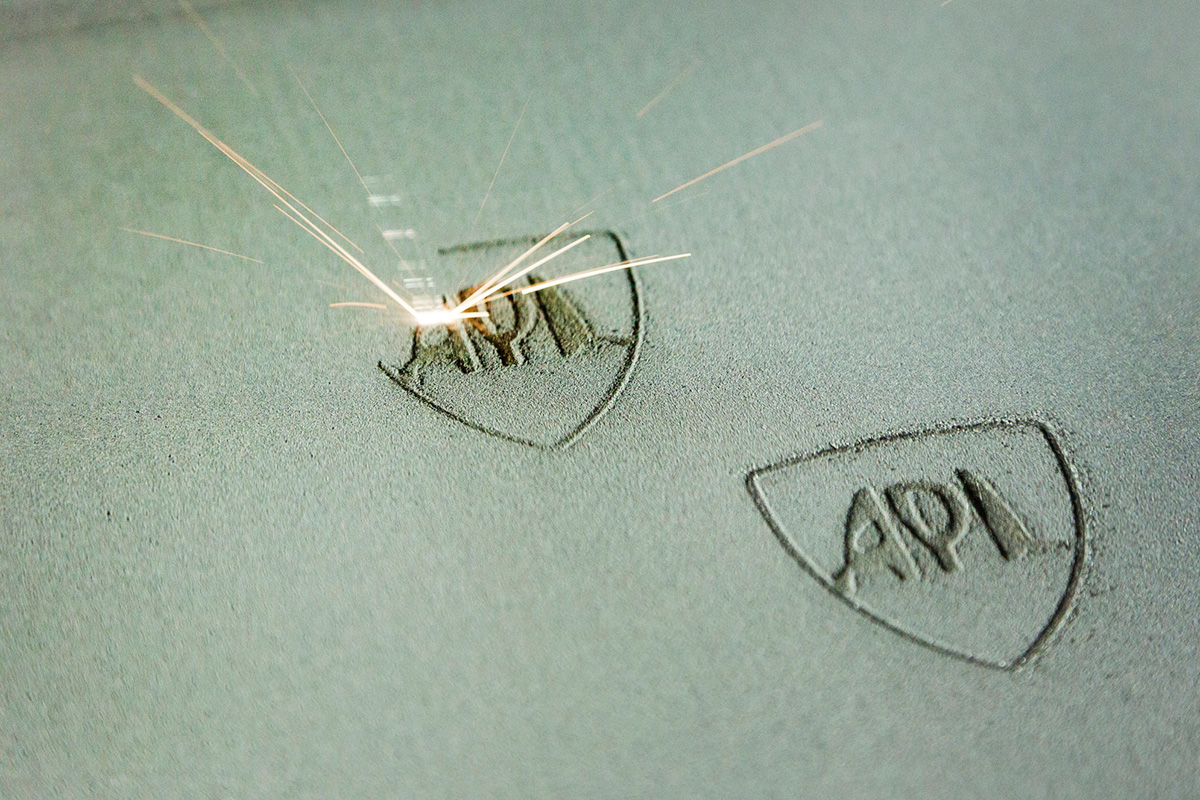

Fabrication

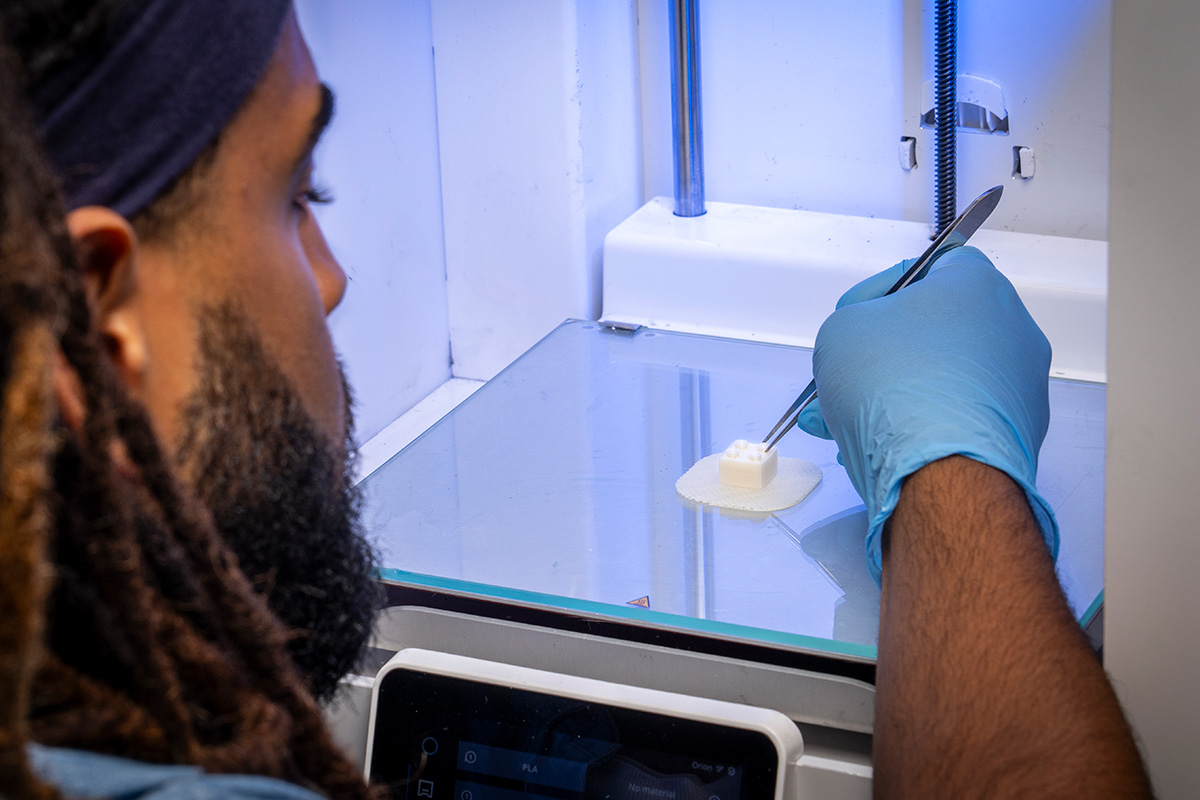

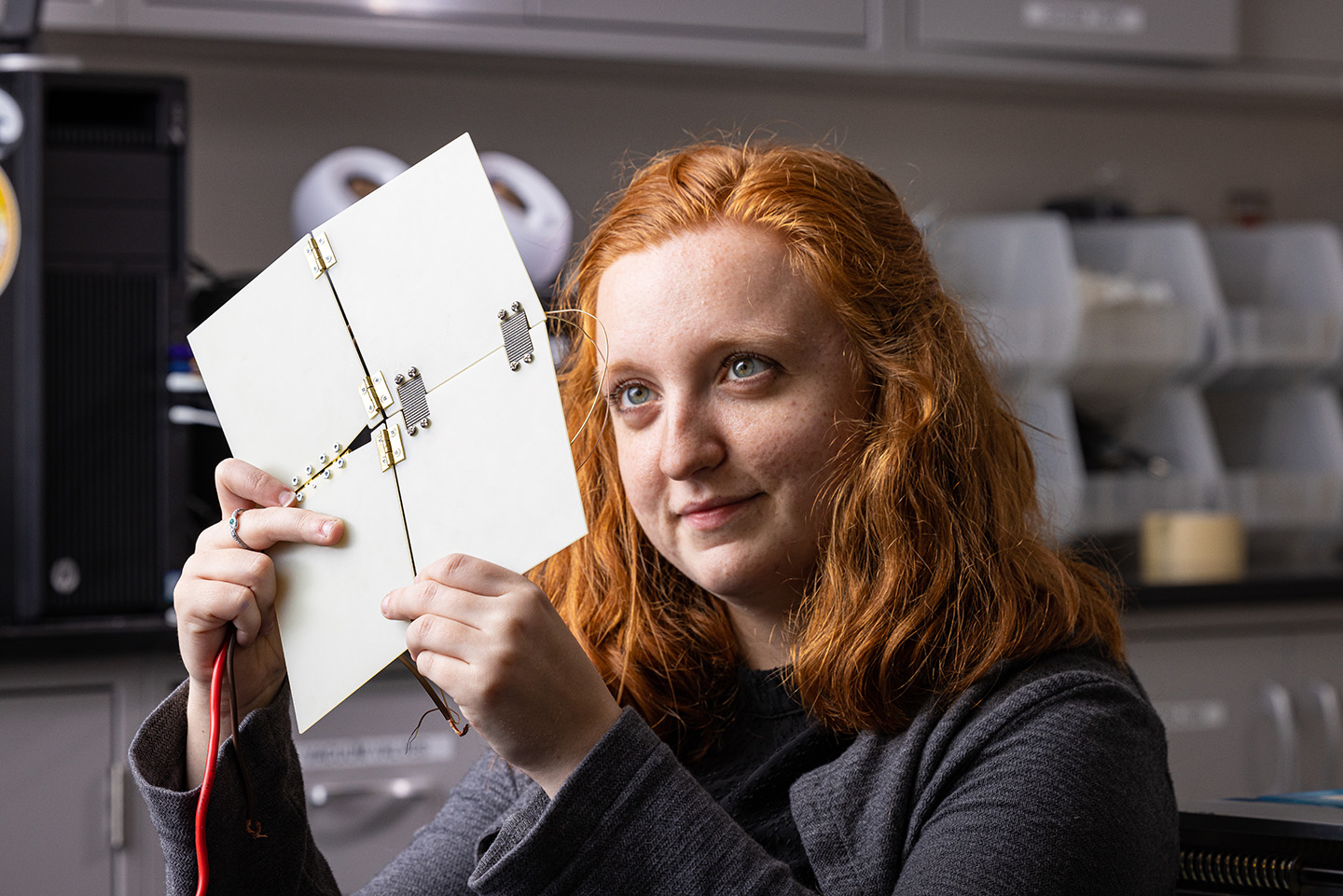

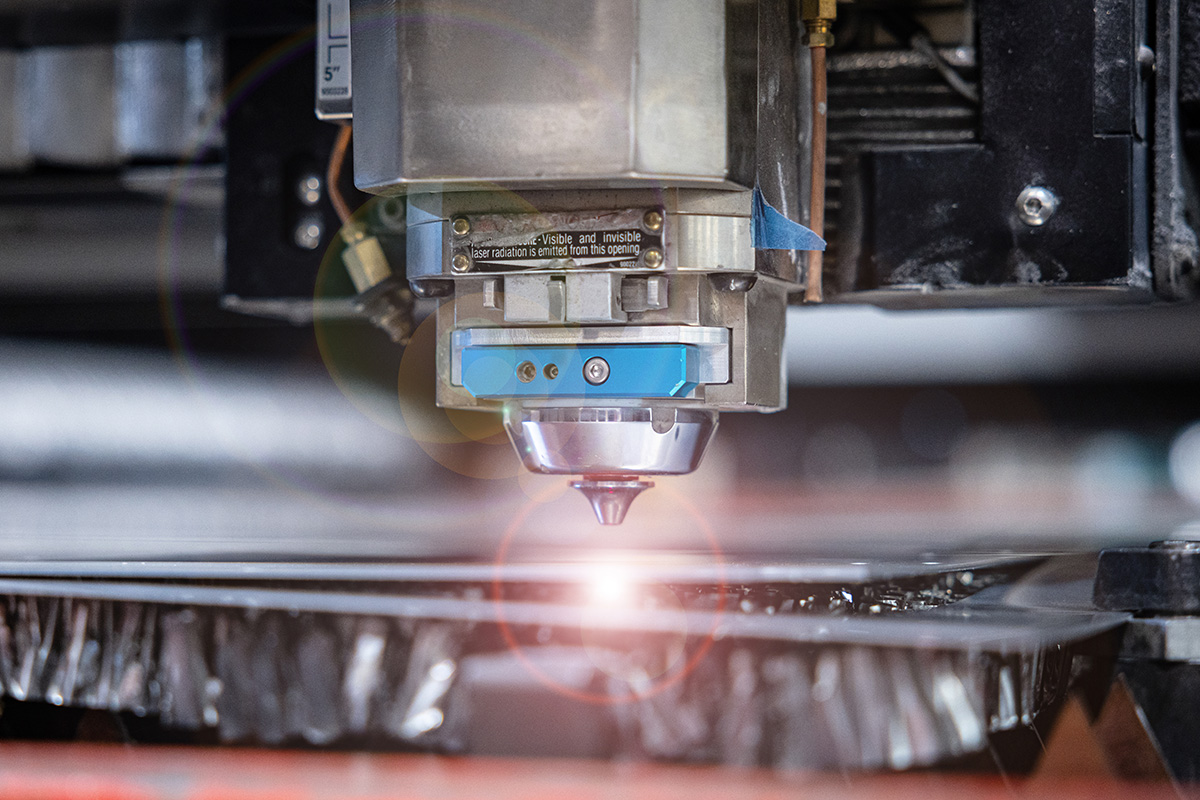

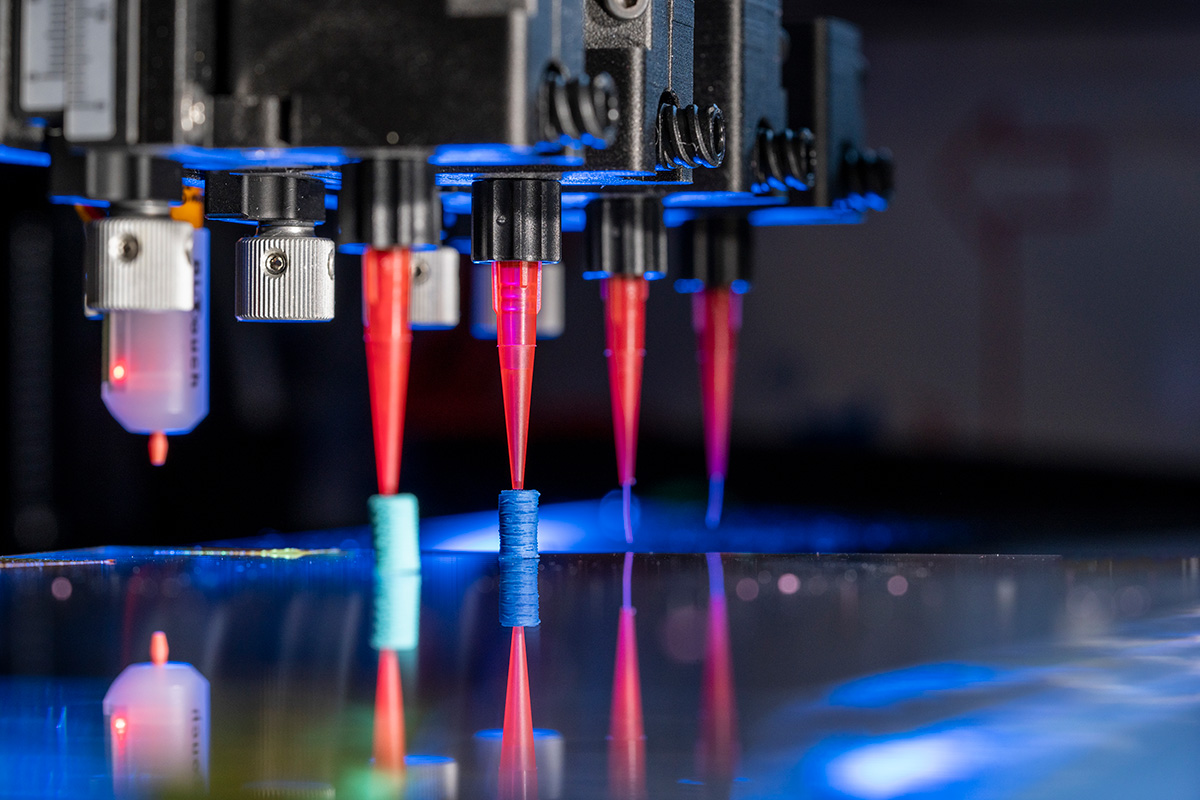

Building advanced components via additive manufacturing, CNC machining, and advanced joining techniques (e.g., laser welding), enabling complex geometries and precise fabrication of metals, polymers, and composites

Quality Control

Conducting real-time inspections with non-destructive evaluation and AI tools, ensuring precision and compliance with aerospace/defense standards through dynamic, data-driven feedback

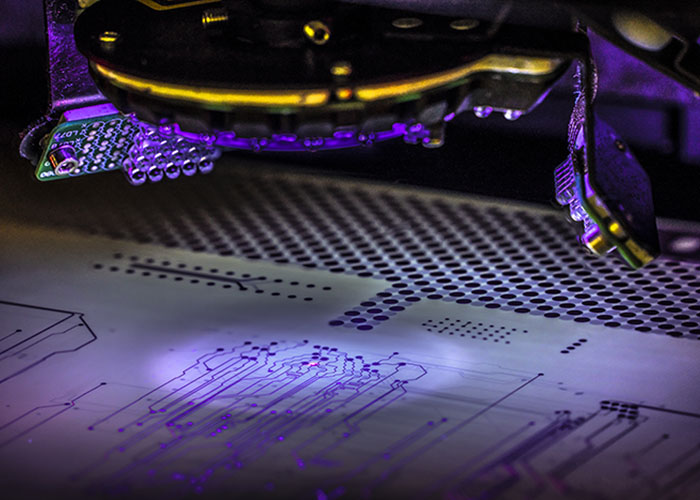

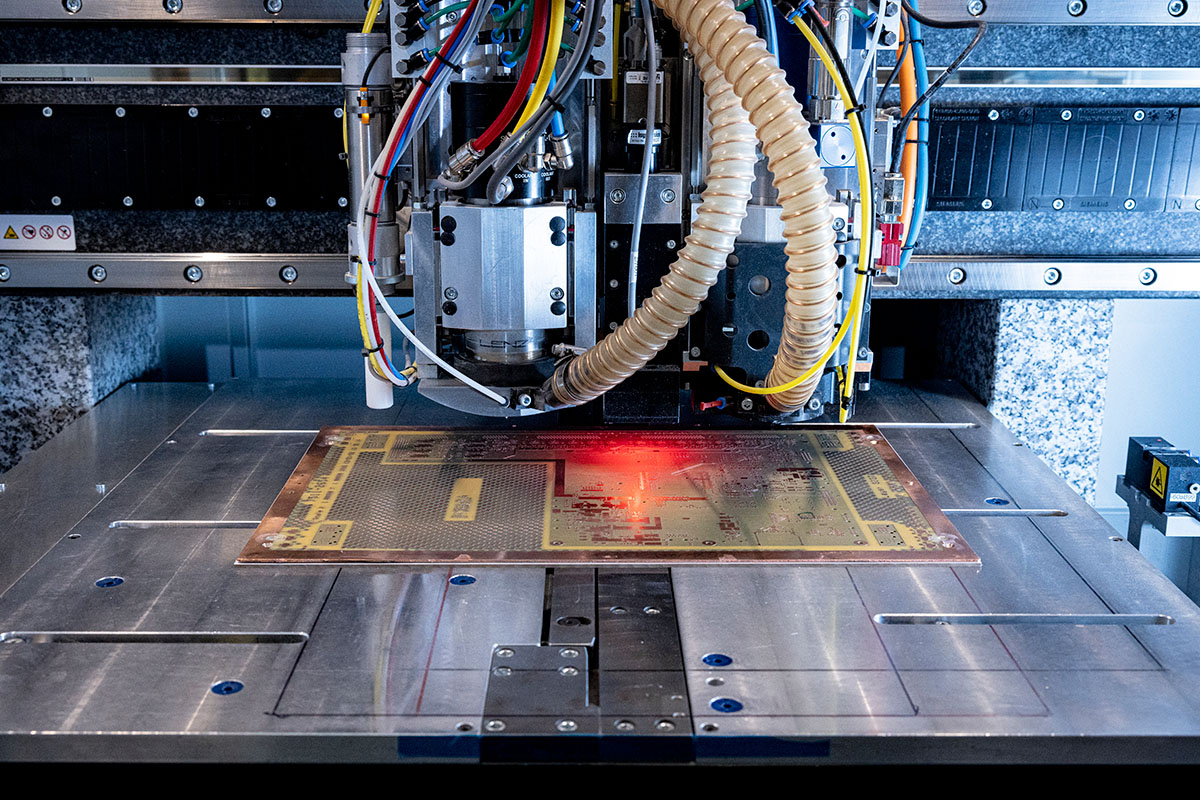

Custom Printed Circuit Board Design and Fabrication

Delivering advanced PCBs for a broad spectrum of applications, from rapid-turn prototypes to highly reliable boards for space missions

Microelectronics Fabrication

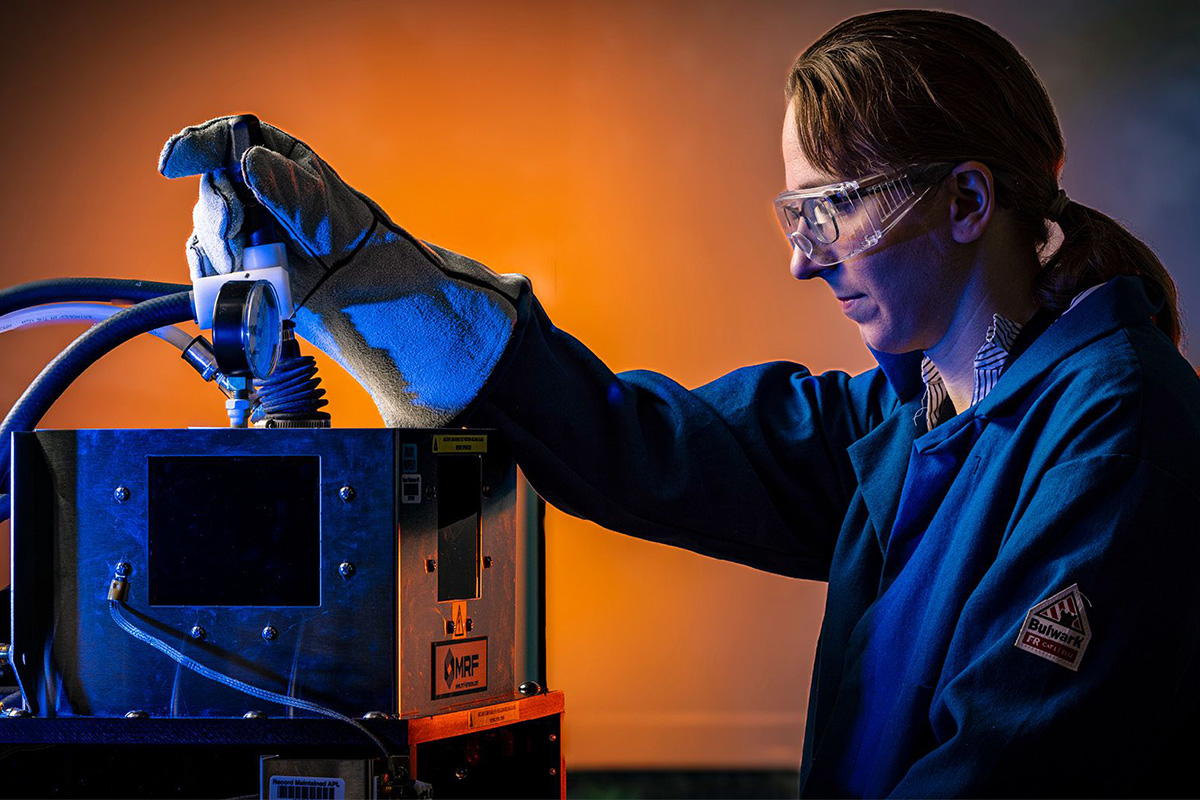

Supporting quick-turn fieldable prototypes and novel material integration, with the ability plate exotic substrates

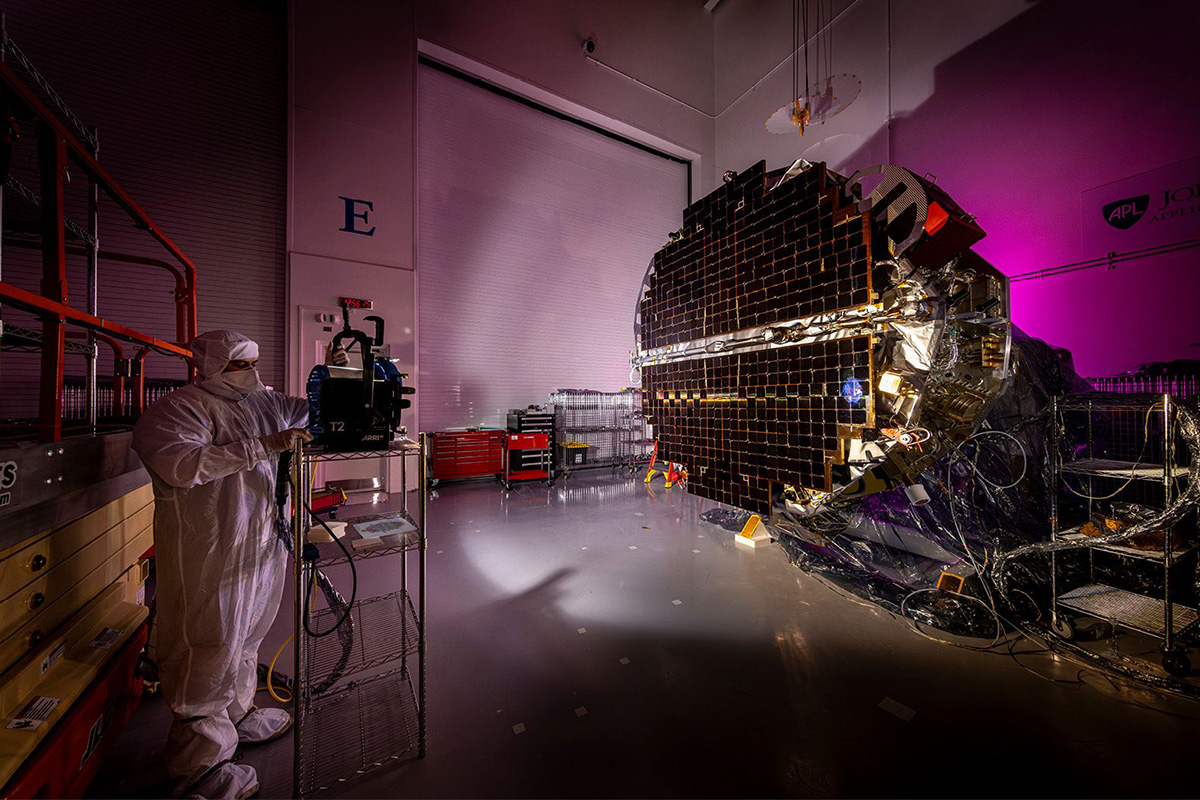

Assembly and Integration

Assembling and integrating high-precision sensor systems and satellites using robotic and manual techniques, delivering operational readiness for mission-critical applications

Testing and Certification

Testing systems under extreme conditions (e.g., thermal, vibration, etc.) and certifying compliance with ISO, NASA, and DoD standards to validate performance and safety

Delivery and Deployment

Coordinating end-to-end logistics and deploying complex systems globally, ensuring seamless integration and field readiness

Focus Areas

Game-Changing Impact

From harnessing the power of additive manufacturing to integrating advanced digital technologies, APL’s researchers and engineers are redefining the art of the possible and creating new opportunities for growth and exploration. We deliver bespoke manufacturing solutions to meet our nation’s biggest challenges.

Materials Development and Characterization

Developing and characterizing cutting-edge materials to accelerate innovation

Deployed Capabilities

Delivering precision-engineered solutions for critical defense and aerospace missions

Standards Development and Leadership

Driving national manufacturing standards to align defense, industry, and research innovations

Expertise

At APL, our culture of taking bold risks, brought to life through inventive prototyping and informed by deep technical expertise, is the basis for our efforts to not merely anticipate the future, but create it.

Related Labs and Facilities

Design, Engineering, and Fabrication

Learn more about our labs, facilities, and expertise in design, engineering, and fabrication.

Steven Storck Chief Scientist, Additive ManufacturingA unique aspect of working at APL is the ability to leverage technology from seemingly unrelated areas. For example, we can take knowledge we apply to missile defense—responding to measurement inputs very quickly and making adjustments even faster—and apply it to additive manufacturing.

Related News

Jan 23, 2026

Flight Engineers Give NASA’s Dragonfly Lift

Nov 12, 2025

New Robotic Arm Opens Doors to Explore Future of Maritime Repair

Sep 17, 2025

An Accelerated Paradigm for Developing Mission-Critical Materials

Aug 5, 2025

Design Standard Update Improves Modular Architecture for Unmanned Platforms

Jun 17, 2025

Johns Hopkins APL, Navy Team up to Advance Additive Manufacturing for Critical Missions

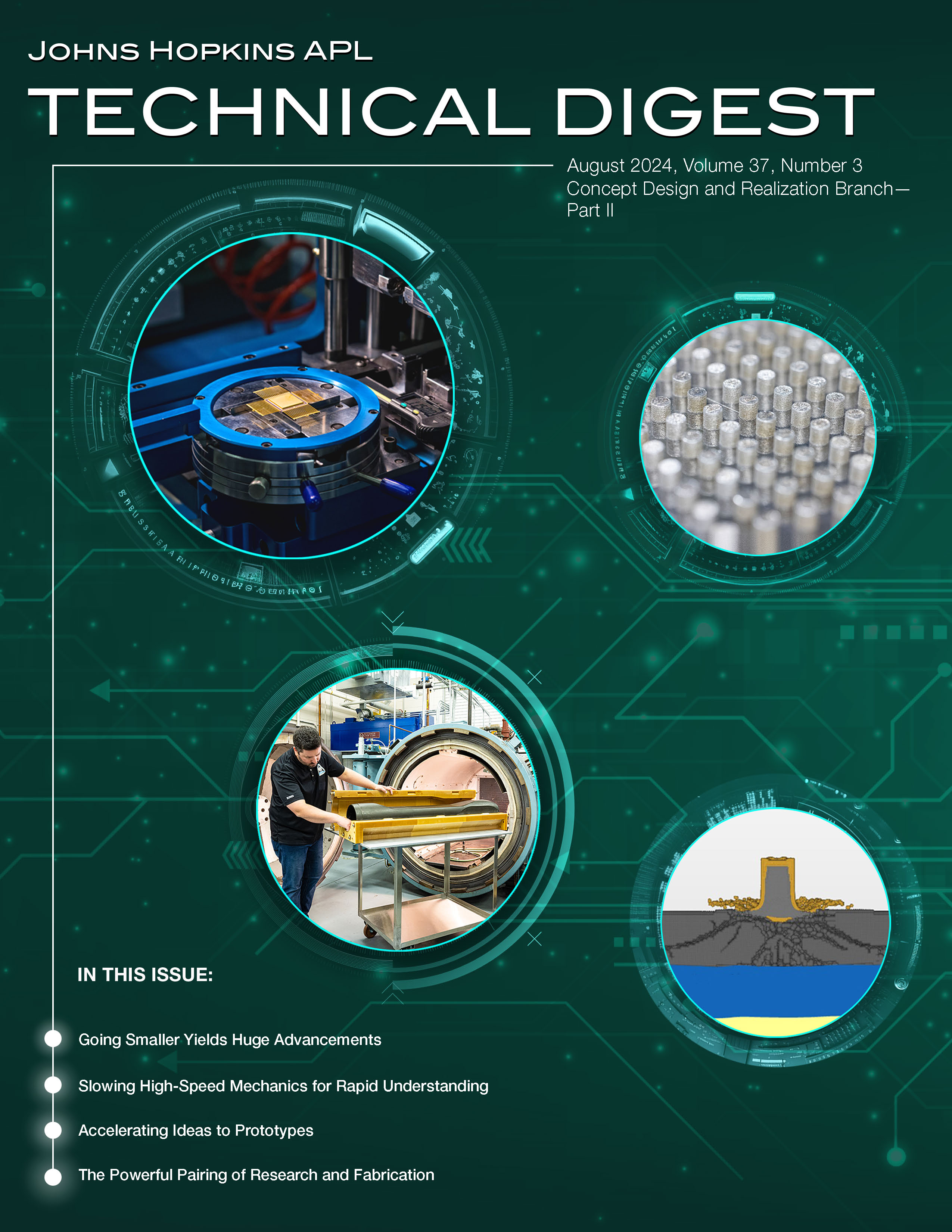

Featured Issues

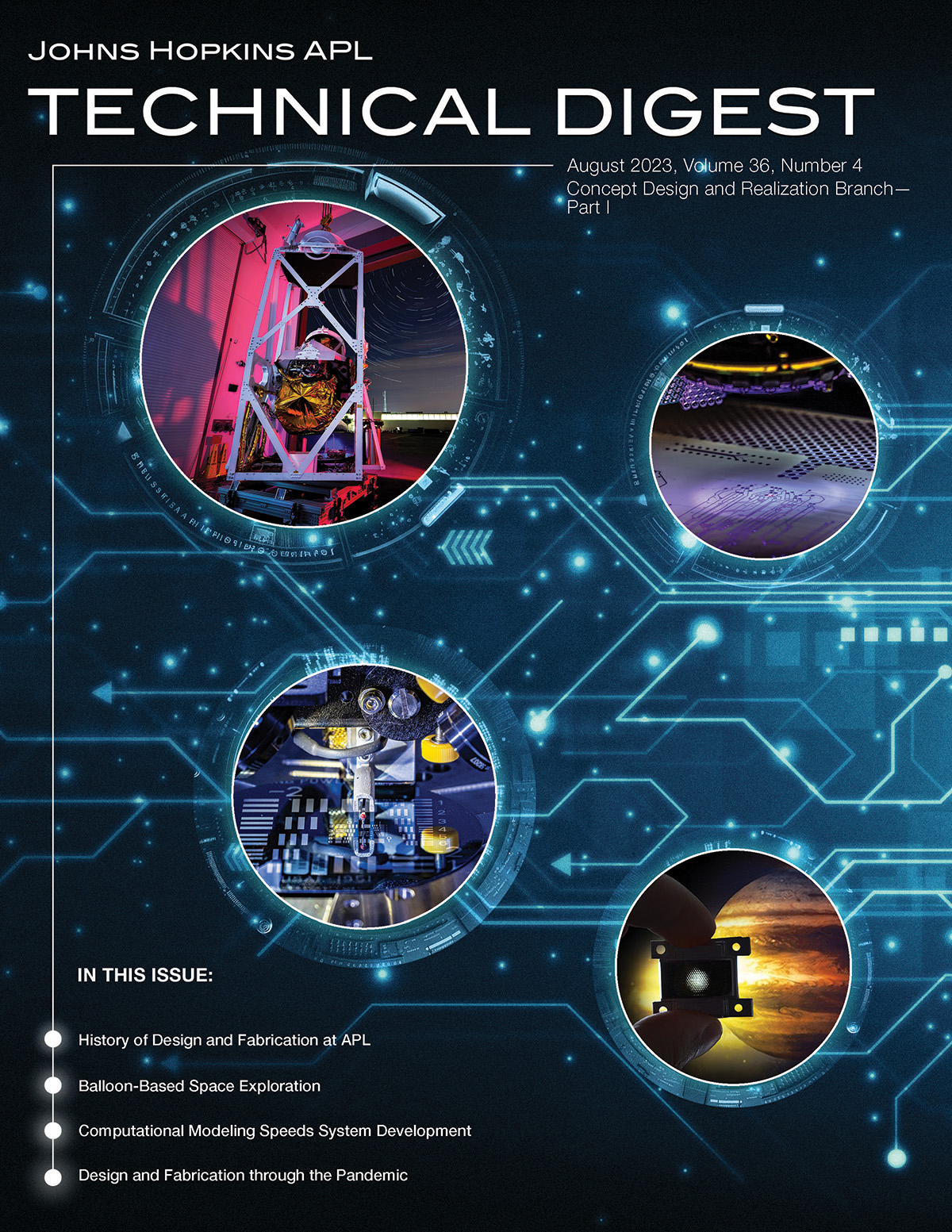

Technical Digest

The Johns Hopkins APL Technical Digest communicates recent advances by APL in science, technology, engineering, and mathematics. Explore these featured issues to learn more about APL’s advanced manufacturing work.

Vol. 37, No. 3 (2024)

Concept Design and Realization Branch—Part II

Vol. 36, No. 4 (2023)

Concept Design and Realization Branch—Part I