News

Flight Engineers Give NASA’s Dragonfly Lift

Audio generated using AI voice technology.

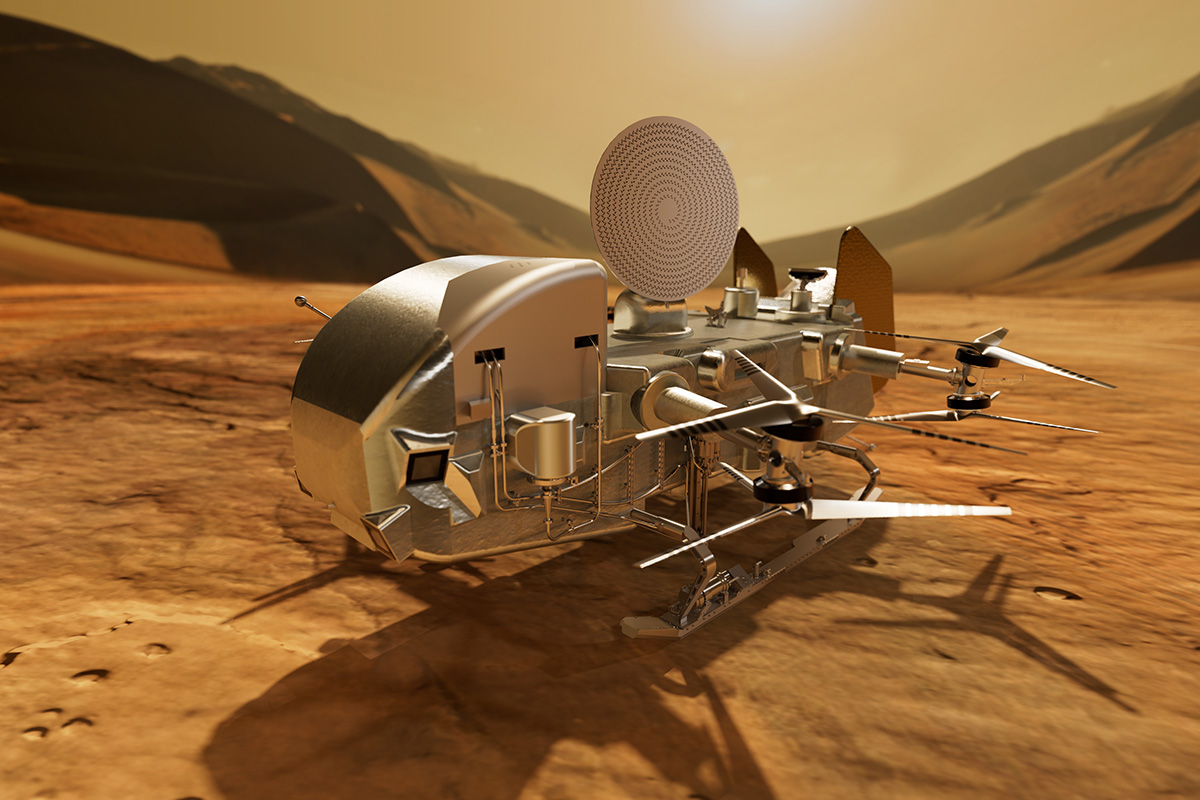

In sending a car-sized rotorcraft to explore Saturn’s moon Titan, NASA’s Dragonfly mission will undertake an unprecedented voyage of scientific discovery. And the work to ensure this first-of-its-kind project can fulfill its ambitious exploration vision is underway in some of the nation’s most advanced space simulation and testing laboratories.

Set for launch in 2028, the Dragonfly rotorcraft is being designed and built at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, with contributions from organizations around the world. On arrival in 2034, Dragonfly will exploit Titan’s dense atmosphere and low gravity to fly to dozens of locations, exploring varied environments from organic equatorial dunes to an impact crater where liquid water and complex organic materials essential to life (at least as we know it) may have existed together.

Aerodynamic Testing

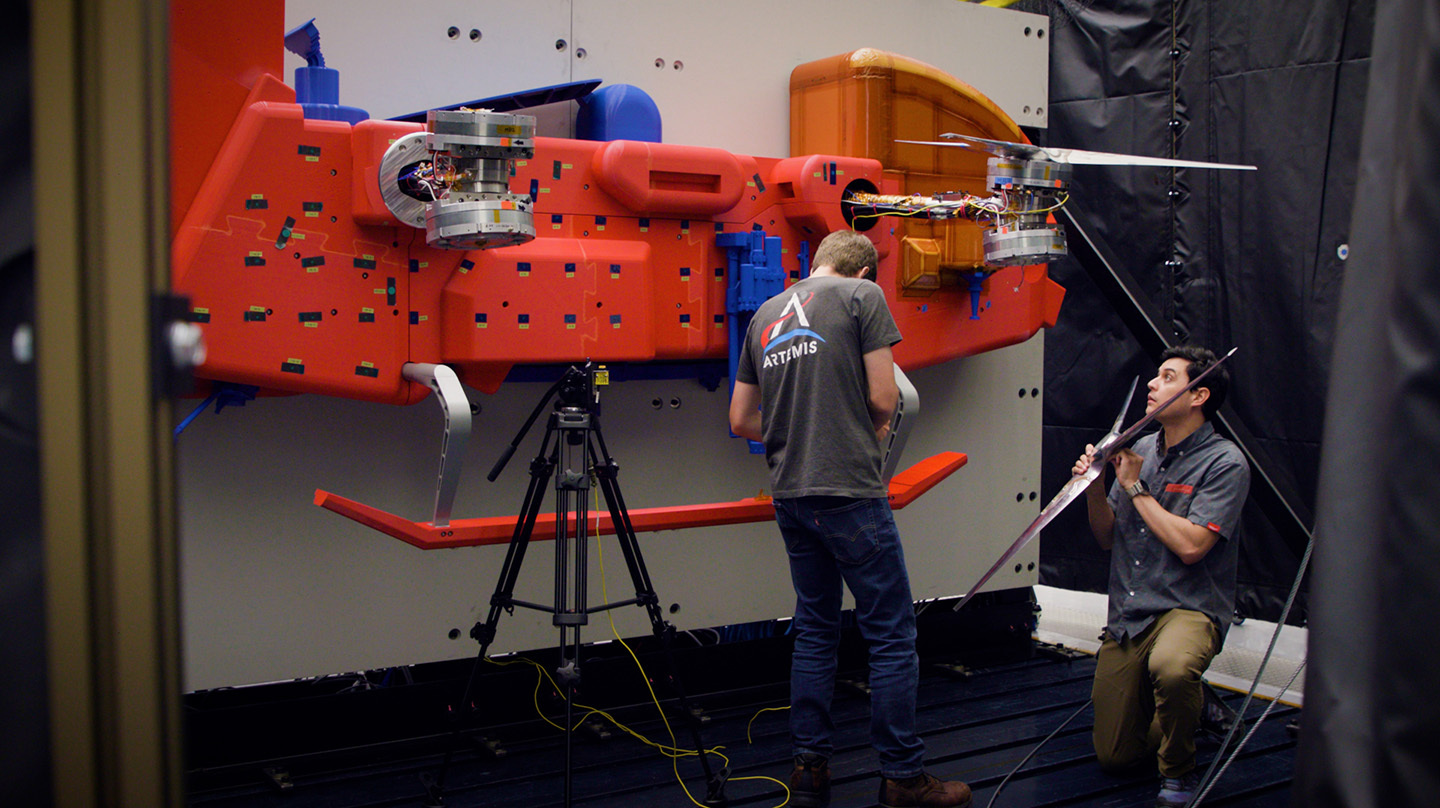

When full rotorcraft integration and testing begins in February, the team will tap into a trove of data gathered through critical technical trials conducted over the past three years, including, most recently, two campaigns at the Transonic Dynamics Tunnel (TDT) facility at NASA’s Langley Research Center in Hampton, Virginia.

The TDT is a versatile 16-foot-high, 16-foot-wide, 20-foot-long testing hub that has hosted studies for NASA, the Department of War, the aircraft industry, and an array of universities.

Over five weeks, from August into September, the team evaluated the performance of Dragonfly’s rotor system — which provides the lift for the lander to fly and enables it to maneuver — in Titan-like conditions, looking at aeromechanical performance factors such as stress on the rotor arms, and effects of vibration on the rotor blades and lander body. In late December, the team also wrapped up a set of aerodynamics tests on smaller-scale Dragonfly rotor models in the TDT.

“When Dragonfly enters the atmosphere at Titan and parachutes deploy after the heat shield does its job, the rotors are going to have to work perfectly the first time,” said Dave Piatak, branch chief for aeroelasticity at NASA Langley. “There’s no room for error, so any concerns with vehicle structural dynamics or aerodynamics need to be known now and tested on the ground. With the Transonic Dynamics Tunnel here at Langley, NASA offers just the right capability for the Dragonfly team to gather this critical data.”