Press Release

Johns Hopkins APL Analyzing Designs, Materials and Operational Impact of Large Structures to One Day Be Built in Space

The Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, is using its expertise in space and extreme-environment materials to evaluate the operational potential of future adaptive, large-scale, space-based manufacturing.

In December, the Defense Advanced Research Projects Agency (DARPA) launched its Novel Orbital and Moon Manufacturing, Materials and Mass-efficient Design (NOM4D, pronounced “nomad”) program to develop foundational materials, processes and designs needed to manufacture large, precise and resilient systems in space.

The program focuses on the design of space-based systems too large to be built on Earth and launched. These structures will have features that enable them to withstand maneuvers, thermal cycles and physical damage typical of space and lunar environments.

The Laboratory’s expertise in space dates back to the 1950s and spans both civil space and national security space. This expertise extends from fundamental research to technologies enabling mission operations and deployed spacecraft, like the Parker Solar Probe that recently became the first to touch the Sun.

“APL was chosen to participate in this DARPA program because of our breadth of scientific and technical expertise as well as our history of successful DARPA collaborations. We will apply our domain knowledge to analyze future operational scenarios enabled by NOM4D technologies,” said Morgan Trexler, who leads APL’s Science of Extreme and Multifunctional Materials program and is the program manager for the Laboratory’s NOM4D effort.

To address the wide-ranging technical challenges presented by NOM4D, Trexler assembled a team of scientists and engineers with deep expertise in materials science, physics, lunar geology, optical sensing, power systems, spacecraft engineering, cislunar space (between the Earth and Moon) and more.

Makerspace in Space

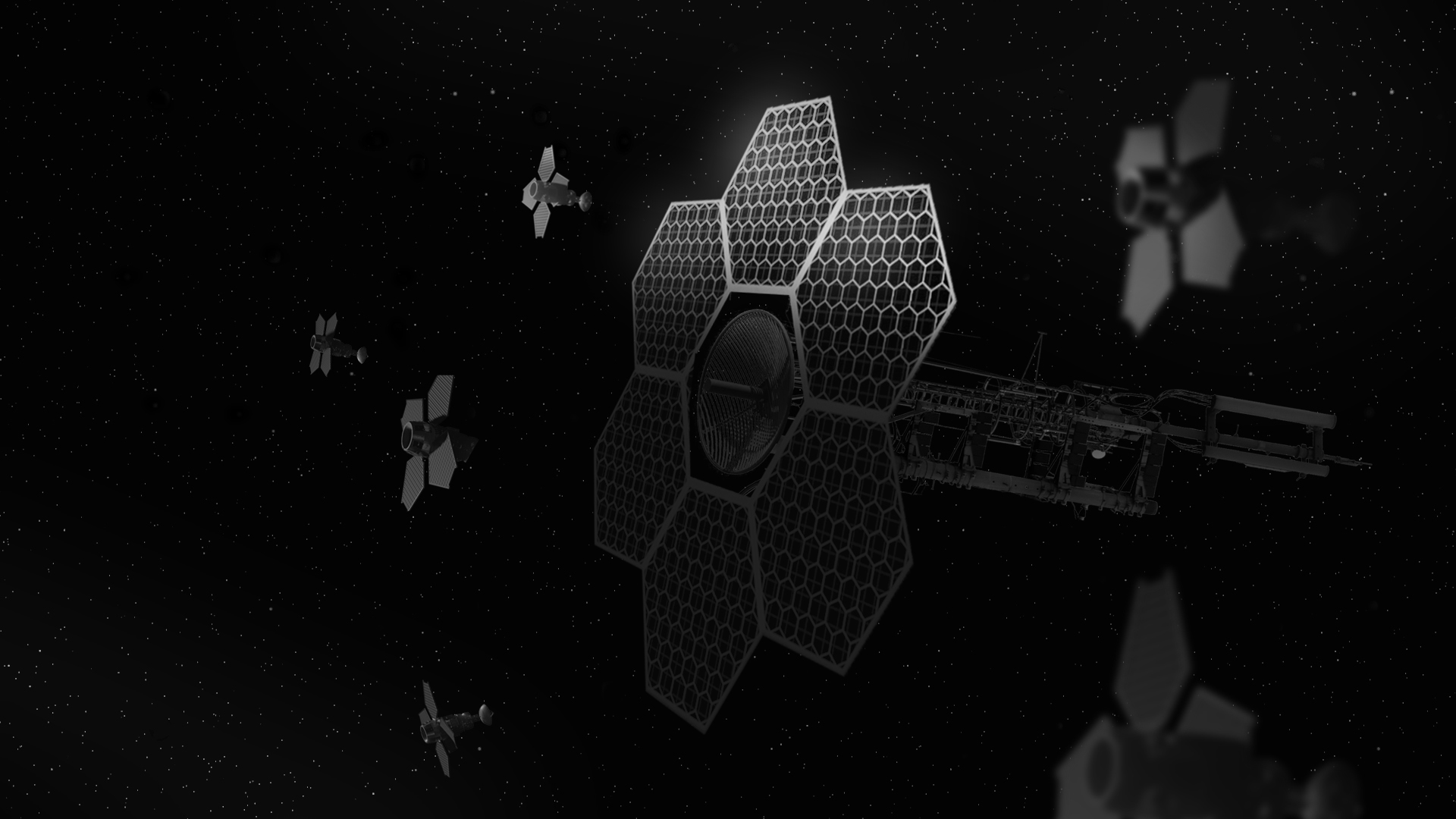

Think of the cislunar environment as the newest makerspace. NOM4D intends to develop the materials, processes and designs to enable future giant manufacturing hubs in orbit.

“There are a lot of restrictions on what you can carry on a spacecraft. Structures need to fold for launch and be able to deploy later, adding design complexity. They need to be incredibly robust to endure the forces of launch. So now if you don’t have to survive the so-called ‘tyranny of launch,’ you have significantly less restrictions on your structures and validation requirements,” explained Ann Darrin, former managing executive in APL’s Space Exploration Sector and a Johns Hopkins University Engineering for Professionals instructor in spacecraft hardware topics. “In-space manufacturing could revolutionize space structures, creating endless new operational capabilities.”

A successful NOM4D program would truly mark a paradigm shift in manufacturing space structures. A persistent manufacturing infrastructure would enable bypassing the restrictions associated with transfer from Earth. Space-based fabrication would leverage native cislunar materials mined and processed in space whenever possible, incorporating advanced materials and components developed on and transported from Earth when necessary. Modular cislunar space systems, made in space, could be continually adapted for different purposes as needs evolve.

NOM4D’s goal of pioneering off-Earth manufacturing maximizes stability, agility, resiliency and adaptability of space systems. In three 18-month phases, the program will tackle increasingly challenging concepts. Phase 1 calls for materials and designs that meet stringent structural efficiency targets using the example problem of a 1-megawatt solar array. Phase 2 will focus on risk reduction and technical maturation to meet structural targets, while maintaining high precision sufficient to meet the requirements of an exemplar 100-meter-diameter radio frequency reflector. Phase 3 calls for a “leap in precision” to enable infrared reflective structures that can be used in a segmented long-wave infrared telescope.

Charting the Path for Resilience in Space

Ground-based fabrication of subscale exemplar structures (as opposed to the full structures) will be used to validate advanced NOM4D materials, manufacturing capabilities and design concepts. Importantly, technologies must be designed to survive and maintain precise operation during potentially destructive events, such as lunar storms and micrometeorite impacts.

“These materials and structures need to be assessed for resilience and performance,” Trexler continued, “but in space there is no precedent for how to test, or what to measure. Collecting meaningful data, understanding the materials and how they perform in the environment of interest, and demonstrating scalability to extremely large structures — all of that is very important, but as of yet undefined. We are well positioned to address these challenges.”

APL’s Multidisciplinary Expertise

The APL team is accustomed to tackling previously unsolved challenges. “At APL, we conduct pioneering research targeting game-changing breakthroughs to benefit national security missions,” said Andrew Merkle, who leads APL’s Research and Exploratory Development Mission Area. “We do this by bringing together multidisciplinary teams of talented scientists and engineers to tackle difficult challenges and invent the future for APL and our sponsors.”

Looking toward the future, the team is thinking beyond the questions of “‘can these be built?’ and ‘how will these be built and tested?’” Trexler explained, “We are thinking about, ‘what can these giant space structures enable?’”

APL’s approach relies on cross-pollination of ideas and domain knowledge. The team of multidisciplinary specialists conceptualized and held a design-thinking exercise, resulting in several “envisioned futures” for NOM4D capabilities, which were subsequently analyzed in depth.

“APL is unique,” Trexler says. “In addition to our strong focus in materials research, we also have expertise in spacecraft design, fabrication and testing, sensing and imaging, power and energy, and operational scenarios in space. So, we understand the whole spectrum and can weave it together. We have all that expertise here and are leveraging the intersections for NOM4D.”