Press Release

Johns Hopkins Applied Physics Laboratory Establishes Additive Manufacturing Center of Excellence

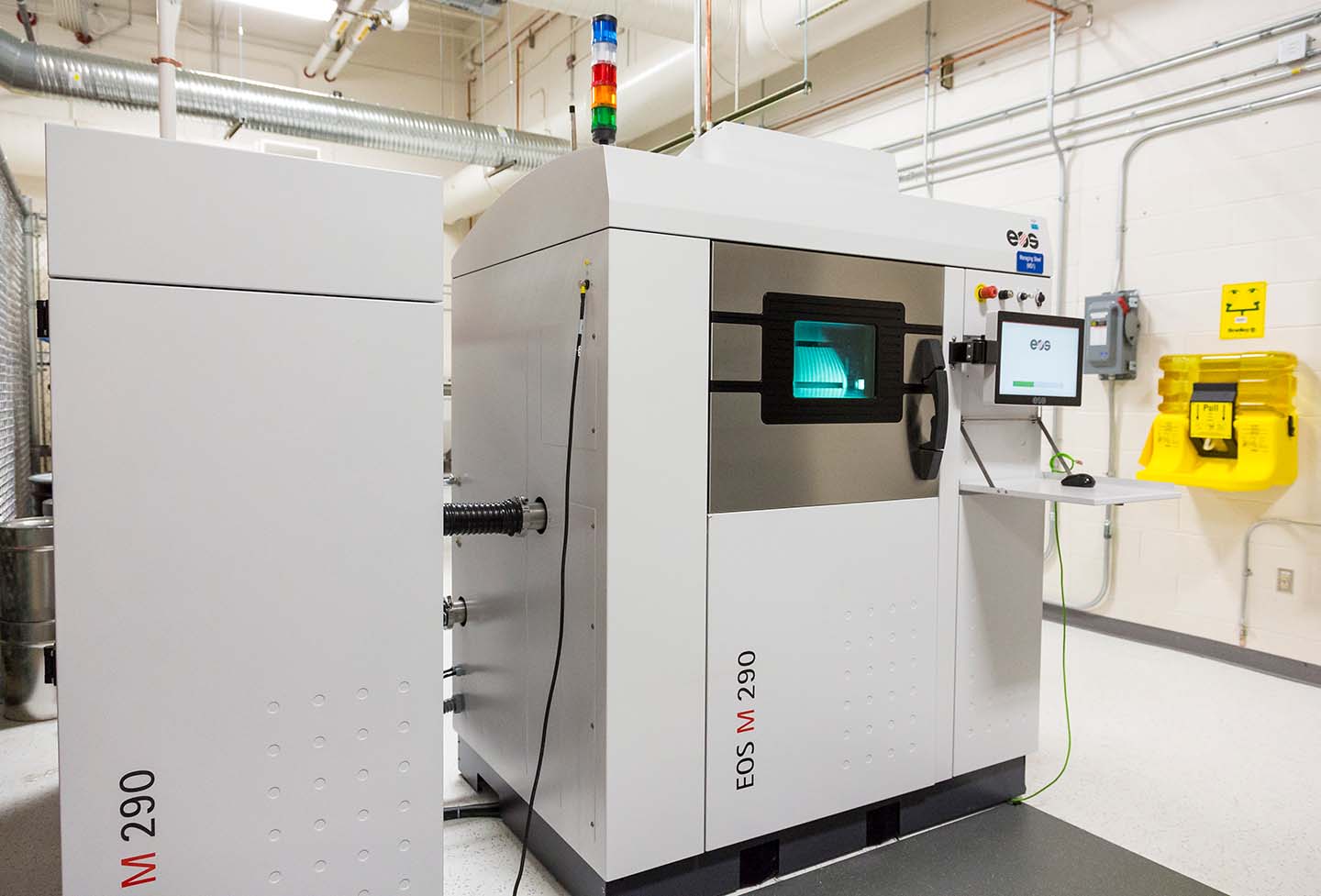

Building on its substantial advanced mechanical fabrication capabilities, the Johns Hopkins University Applied Physics Laboratory (APL) in Laurel, Maryland, has established a center of excellence to guide major advances in additive manufacturing, commonly known as 3-D printing.

The center will guide APL efforts to creatively apply this disruptive technology, which is rapidly revolutionizing how a wide variety of parts and systems are designed and built. The profound transformation caused by additive manufacturing is being accompanied by a wave of research on new materials, the potential integration of electronics into devices as they are made, the printing of biological structures and the emergence of nano-engineering.